The float switches are fine as is, although I question the operation in a boil kettle full of hops. As far as the disconnect switch goes, you learn pretty quick how not to boil over the kettle and turn the element down when you get there, and if you overshoot, you just turn it down as well, I've never felt the need to pull the power in either case. But if the switch makes you happy, it's your money.RubberToe wrote:The point of having a switch in front of the element is so that you can turn it off when you need to (boil over, overshoot temp, etc) without turning the PID controller off. The float switch is just a precaution so you don't run the element dry. The float switches should also control the contactor so they aren't handling the element current; they shouldn't at least... I didn't go back to the diagram.mr x wrote:What is the point of disconnecting the power from the elements using a contacter? Why not just pull the plug? I understand that the float switches won't handle the current, so I see the point of contactors there.

Everwood Avenue Brewery Build

- mr x

- Mod Award Winner

- Posts: 13764

- Joined: Fri Sep 24, 2010 5:30 pm

- Location: Halifax/New Glasgow

Re: Everwood Avenue Brewery Build

At Alexander Keith's we follow the recipes first developed by the great brewmaster to the absolute letter.

- RubberToe

- Award Winner 13

- Posts: 3743

- Joined: Mon Mar 14, 2011 9:47 am

- Name: Rob

- Location: Dartmouth

- Contact:

Re: Everwood Avenue Brewery Build

Yeah, for the extra cost, like $10-$20 the switch is worth it to me. I haven't have any boil overs but sometimes I just want to kill the element for a bit, it's pretty useful, the PID controller has a bit of a delay itself.

Electric Brewery Build

On tap at RubberToe's:

Sometimes on a Sunday Belgian Dubbel, Oaked Old Ale, Ordinary Bitter

On tap at RubberToe's:

Sometimes on a Sunday Belgian Dubbel, Oaked Old Ale, Ordinary Bitter

- GillettBreweryCnslt

- Vendor

- Posts: 1935

- Joined: Thu Nov 11, 2010 11:24 am

- Name: David Gillett

- Location: Hammonds Plains

- Contact:

Re: Everwood Avenue Brewery Build

/end wiring discussion

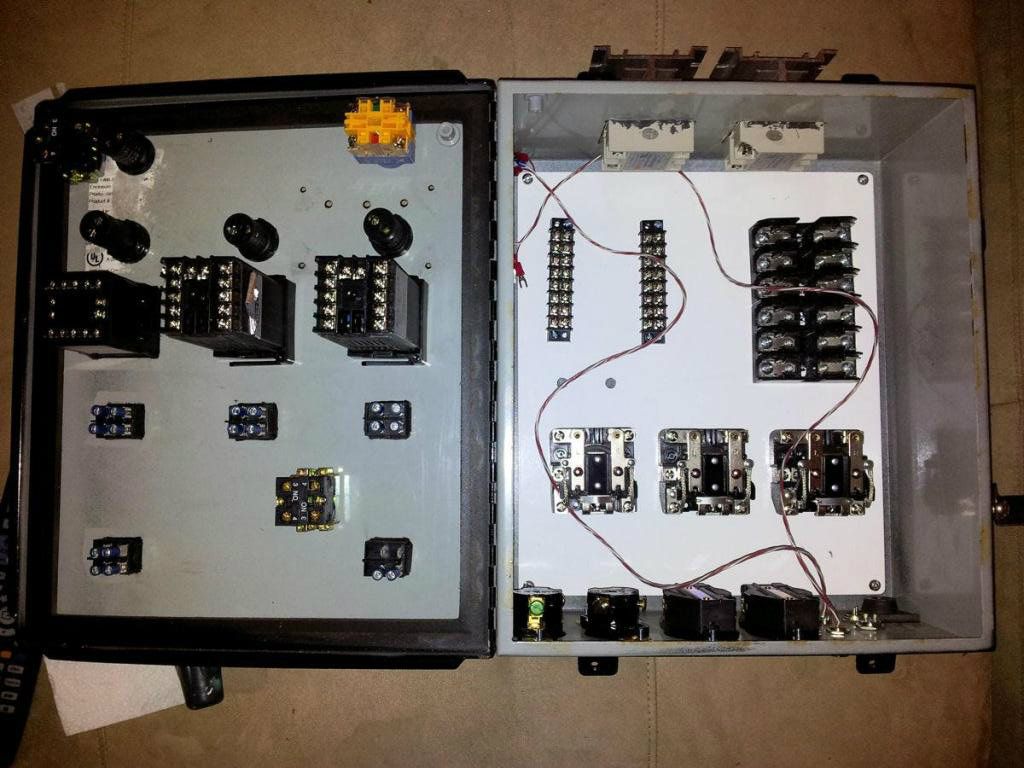

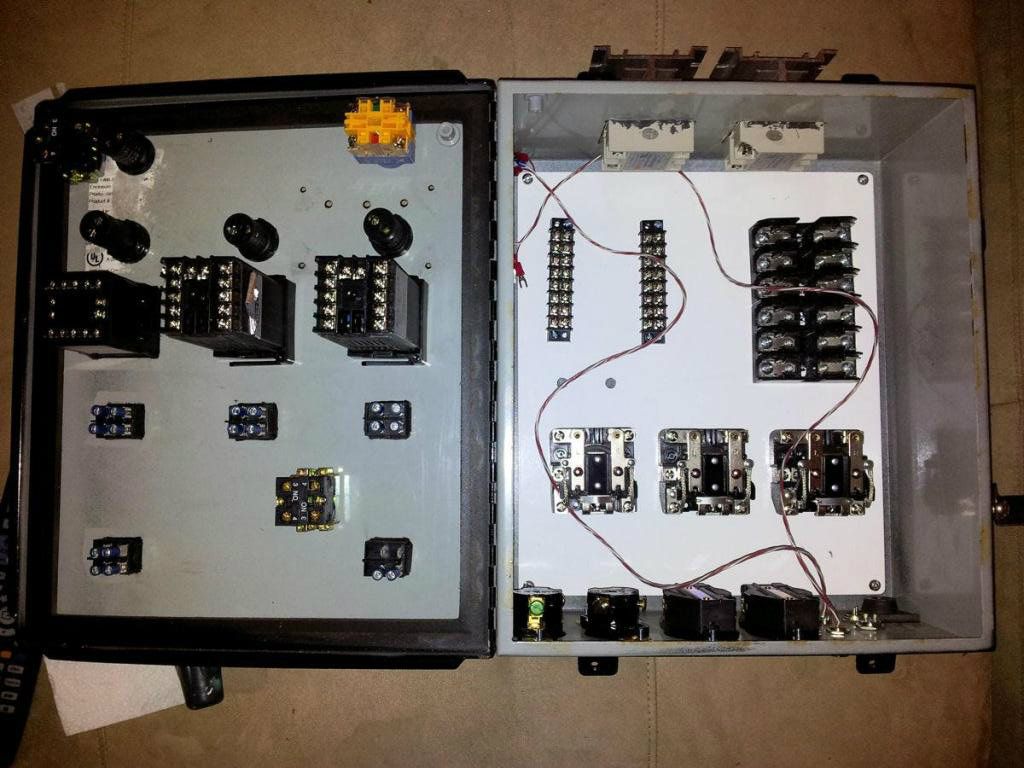

Moving along, So after a week or two or delay to build the keezer, I continued work on the panel over the past couple of days. Here are some pics to update the progress.

Cutting out the holes, I had concerns about using a dremel instead of paying for the water-jet cut, but I have to be honest, it was easy and I don't really get why anyone would pay to have their panel cut when you can easily do it yourself. But to each their own.

After a quick paint and installation of the parts I'm ready to start wiring tonight. I didn't dust the outside before taking this picture, but trust me, it's shiny!

I've got a fair bit of space inside so I'm hoping wiring goes well and I can tidy it up nicely.

Moving along, So after a week or two or delay to build the keezer, I continued work on the panel over the past couple of days. Here are some pics to update the progress.

Cutting out the holes, I had concerns about using a dremel instead of paying for the water-jet cut, but I have to be honest, it was easy and I don't really get why anyone would pay to have their panel cut when you can easily do it yourself. But to each their own.

After a quick paint and installation of the parts I'm ready to start wiring tonight. I didn't dust the outside before taking this picture, but trust me, it's shiny!

I've got a fair bit of space inside so I'm hoping wiring goes well and I can tidy it up nicely.

- LeafMan66_67

- Award Winner 2

- Posts: 4600

- Joined: Fri Mar 02, 2012 7:10 am

- Name: Derek Stapleton

- Location: Lower Sackville, NS

- jeffsmith

- Verified User

- Posts: 4922

- Joined: Tue Apr 26, 2011 4:18 pm

- Name: Jeff Smith

- Location: Amherst, NS

- Contact:

Re: Everwood Avenue Brewery Build

Looks great so far!

Who is online

Users browsing this forum: No registered users and 0 guests